Specification

Pacific Plastics IPS SDR series of PVC pipe is produced for use in the pressure applications in which the maximum operating temperature is 140°F. The compound is PVC 1120 Type 1 Grade 1, with a cell class of 12454B.

The SDR series listed below, is produced in strict compliance to ASTM D2241. It is listed with NSF and complies with NSF/ANSI Standard 14 and Standard 61.

SDR series of PVC pipe are installed per ASTM D2855. The joints should conform to ASTM D2672, the solvent cement to ASTM D2564 and the primer to ASTM F656.

Our SDR series of PVC pipe is produced in the following categories:

- White SDR 13.5, SDR21, SDR26, SDR32.5, SDR41, SDR64 for use in Potable Water applications.

- Sizes 1/2″ – 12″ are produced in White color, 20 foot lengths and Belled End.

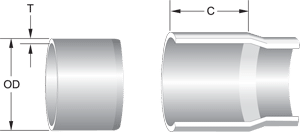

The outside diameter and wall thickness of the SDR Series of PVC pipe are measured in accordance to ASTM D2122 and are shown in the following table:

| Size | OD | C | T - SDR13.5 | T - SDR21 | T - SDR26 | T - SDR32.5 | T - SDR41 | T - SDR64 |

|---|---|---|---|---|---|---|---|---|

| 1/2 | 0.840 | 1.00 | 0.062 | 0.045 | ||||

| 3/4 | 1.050 | 1.25 | 0.060 | 0.048 | ||||

| 1 | 1.315 | 1.50 | 0.063 | 0.052 | ||||

| 1 ¼ | 1.660 | 1.75 | 0.079 | 0.064 | 0.056 | |||

| 1 ½ | 1.900 | 2.00 | 0.090 | 0.073 | 0.058 | |||

| 2 | 2.375 | 2.25 | 0.176 | 0.113 | 0.091 | 0.072 | ||

| 2 ½ | 2.875 | 2.50 | 0.213 | 0.137 | 0.110 | 0.087 | ||

| 3 | 3.500 | 3.25 | 0.259 | 0.167 | 0.135 | 0.108 | 0.085 | |

| 4 | 4.500 | 4.00 | 0.333 | 0.214 | 0.173 | 0.138 | 0.110 | |

| 5 | 5.563 | 4.50 | 0.136 | |||||

| 6 | 6.625 | 6.00 | 0.316 | 0.255 | 0.204 | 0.162 | 0.104 | |

| 8 | 8.625 | 6.00 | 0.410 | 0.322 | 0.265 | 0.210 | 0.135 | |

| 10 | 10.750 | 7.50 | 0.511 | 0.413 | 0.331 | 0.262 | 0.168 | |

| 12 | 12.750 | 8.50 | 0.606 | 0.490 | 0.392 | 0.311 | 0.199 |

OD – Outside Diameter

T – Wall Thickness

C – Approximate Bell Depth

PSI – Pressure Rating